Pain Point

Short procurement cycle

Short product renewal cycle,high pressure of delivery period.

Inefficient work

Matching customer needs,high chance of changing production plan

Decision-making lacked

Manual reports affect the speed of business decisions

Management difficulted

Complex injection molding manufacturing site management,difficult to track accurately.

Complex BOM structure

The product BOM structure is complex.There are more configurable types of materials.

Mold manage stricted

Mould life, repair, maintenance, etc.have high technical requirements.

The Solutions

UMS collects the location, working status and fault status of injection molding machines in real time and transmits them to the platform to realize real-time online monitoring and remote diagnosis of injection molding machines, as well as calculating the utilization rate, fault and energy consumption of injection molding machines.

30%

Efficiency improve

45%

Closed-loop control improve

23%

Process improve

35%

Traceability enhance

24%

Equipment improve

Injection Molding Solution

Kanban and Analytics

Reports, alarms, real-time kanban and operational kanban.

Job Plan Import Sorting

Importing shop floor job plans into the uMES system to perform task scheduling.

Paperless production process control

Paperless process execution,process monitoring and management of the production process.

Equipment status monitoring and acquisition

The underlying industrial network enables equipment, networking and status monitoring

Full lifecycle traceability

Based on product traceability analysis, the monitoring and timely detection of defects

Product data system integration

Product design data and work order material integration.

Value

Customer Value

Unified Management

Efficient control of workshop production management process,covering collaborative operations between workshops.

Fine management

Intelligent batching, refine the production index,strengthen the assessment, reduce the consumption of raw materials

Improve Quality

Reinforcing the quality inspection and improvement process,meet the new level of customer requirements

Building Models

Building a big data mode,unleash the potential value of production data

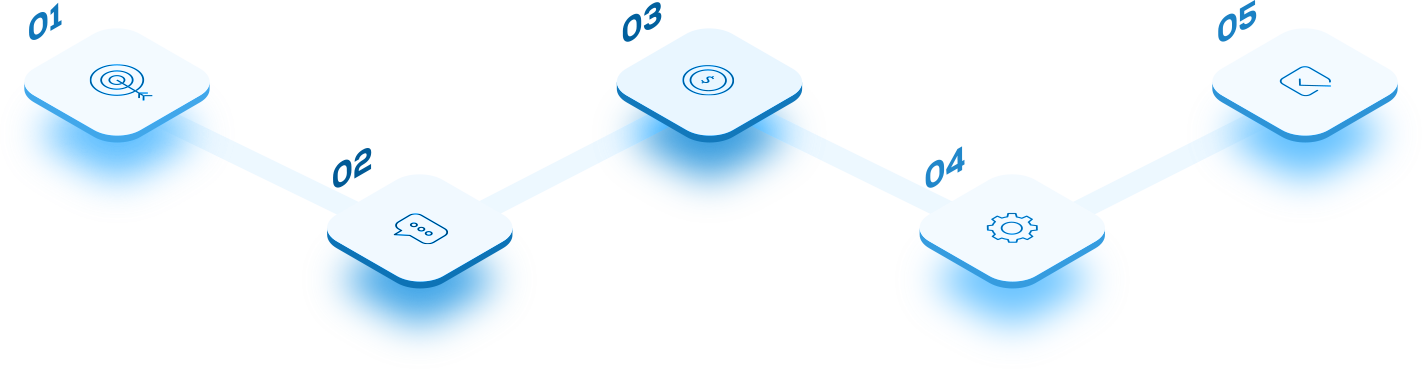

Project Landing Process

01Customer requirements gathering

Specific application requirements from client-side users.

02Communicate product solutions

PPT presentation to enhance mutual understanding.

03Pre-sales project evaluation

Evaluate project feasibility based on specific functional requirements and output corresponding functional solutions.

04Confirm project offer

Both parties confirm the project quotation according to the program details.

05Signing the contract

Signing cooperation agreement and opening project cooperation.